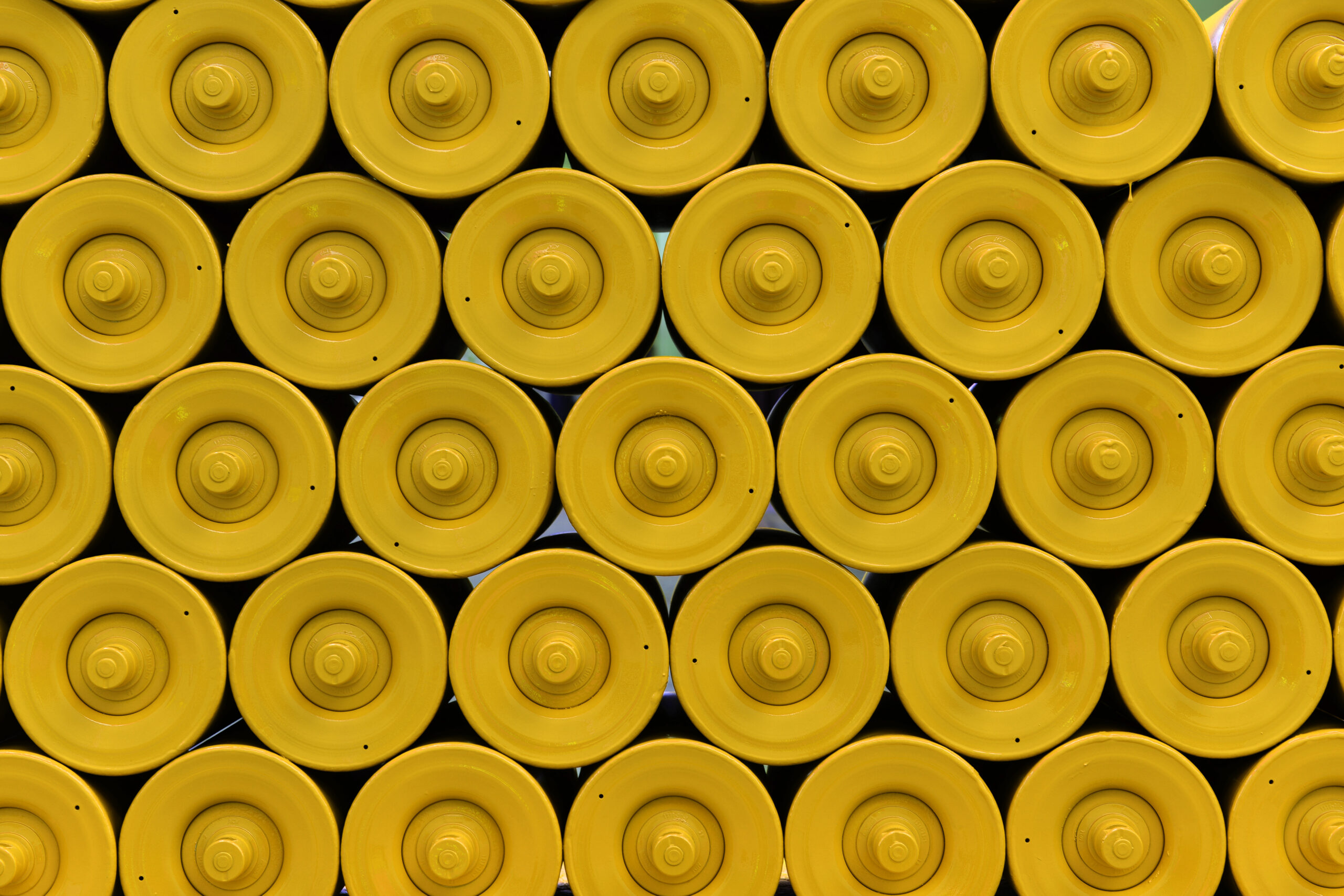

Roller Diameter

89, 102, 114, 127, 152, 178 and 194mm

Tube Material

350 Grade Steel, 350 Grade Galvanised Steel, 3CR12 Stainless Steel

Bearing Sizes

6205, 6305, 6306, 6307, 6308, 6309, 6310 and 6411

Shaft Sizes

26 mm - 56 mm

Housing

Welded pressed cap

Improve performance

Our unique design and manufacturing process has resulted in a PROK Standard Steel roller engineered to ensure optimum performance, reliability and durability.

Other features also include its belt friendly design which means it is not prone to the “pizza cutter” effect, has high impact resistance and is equipped with precision bearings greased for life.

The PROK Standard Steel roller high quality tube is manufactured for conveyor rollers conforming to SABS 657/3 standards and its shell can be hot vulcanised rubber lagged or galvanised wear coated for special applications.

PROK Steel Features

PROK Steel Features

Customised manufacturing to meet all specifications

Our unique design and local manufacturing process has resulted in a steel roller engineered to ensure optimum performance, reliability and durability.

Flanged bearing housing

Manufactured in Australia, the flanged bearing housings provides added belt protection and surperior mechanical performance when compared with a "T-Style" housings.

Triple-Labyrinth Sealing System

PROK custom designed triple-labyrinth seal has been tried and tested in the harshest mining environments throughout Australia and the wider world.

View more rollers

Don’t get left behind

We don’t stop chasing performance, and neither should you. Optimise your site today.